Product Details

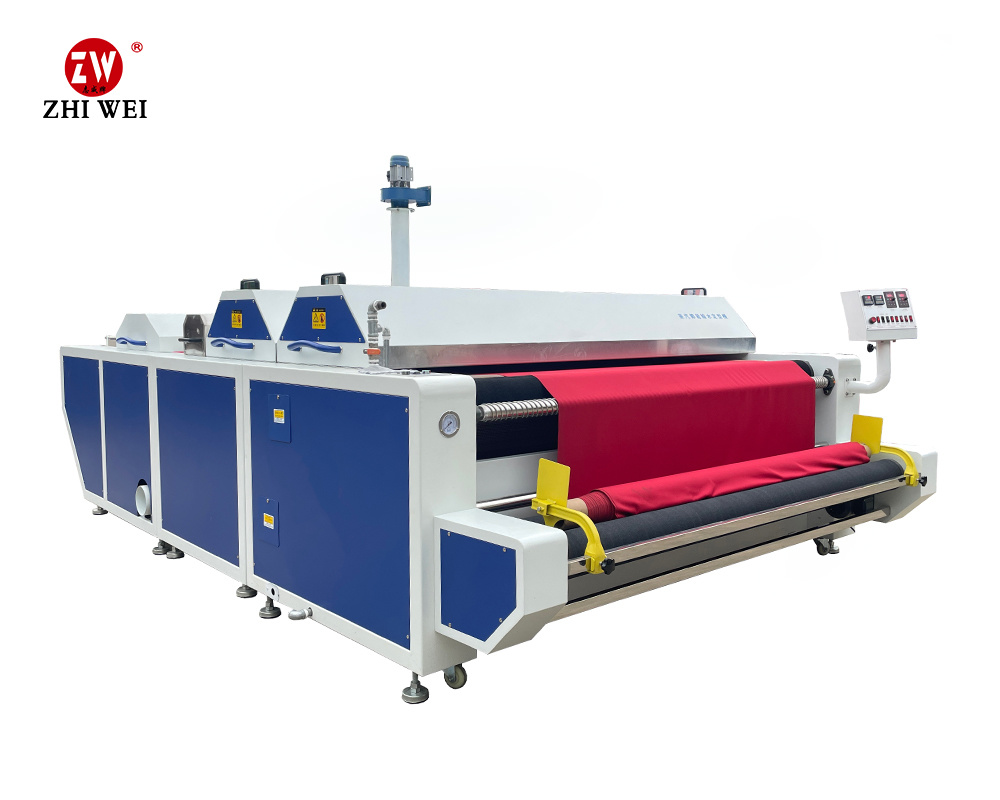

ZW-SN-8788 Large Intelligent Pre-shrinking Shaping Machine

- Description

-

Product Name:Large Intelligent Pre-shrinking Shaping Machine

Model:ZW-SN-8788

Technical Parameters:Voltage Total Power Steam Consumption Working Speed Working Width Body Size AC 220V 8KW 100-150kg/n 0-50m/min 2050mm 4400×2700×2400mm

(Manual measurement may have deviations)Product Features:

1. Fabric Release: The placement position of the processed fabric, combined with the foot pedal pause function, greatly improves the release of materials, reducing the possibility of fabric falling or jamming during the material change process due to excessive speed;

2. Guide Shaft: The power source for transmission. Driven by a three-phase gear reduction motor, it can be speed adjusted by frequency conversion, allowing for convenient stepless speed regulation;

3. Electric Eye: Controls the automatic fabric release amount with an electric eye, keeping the original fabric in a certain vertical arc, allowing the feeding fabric to enter the pre-shrinking area without tension and evenly;

4. Off-center Belt Device: Micro-switch sensing effectively prevents the occurrence of belt deviation;

5. Steam Area: The main working area of the machine, where the fabric achieves pre-shrinking and shaping under the action of high-temperature steam in two zones. The heating temperature and steam amount can be selected according to the fiber properties of different fabrics, thus meeting the requirements of different processes (steam heating can reach 250℃).

6. Drying Area: The area for drying and heating treatment of the fabric, using steam copper pipes for heat sources on both upper and lower sides combined with high-temperature aluminum plates for drying.

7. Dehumidifying Cooling Shaping Area: Uses a downward suction vacuum method to achieve dehumidifying cooling shaping of the fabric;

8. Material Collection and Folding Area: Achieves back-and-forth folding of the fabric through a motor reducer, and the fabric swinging width can be adjusted according to actual process requirements.

9. Newly configured video monitoring for the fabric release and output area, greatly facilitating independent control and monitoring of fabric release and output status, reducing the need for workers to frequently walk back and forth to observe the release situation;

10. Fabric Inspection Light Basin: Allows observation of debris and other defects on the fabric;

11. Independently controlled fabric rolling area, allowing for manual speed adjustment to control the tightness of the fabric roll;

12. Automatic Sensing Length Counter: Automatically counts the length of the fabric, stopping automatically after the fabric is completed (can convert between meters and yards);

Related Products

Product Consulting

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will contact you as soon as possible