Product Details

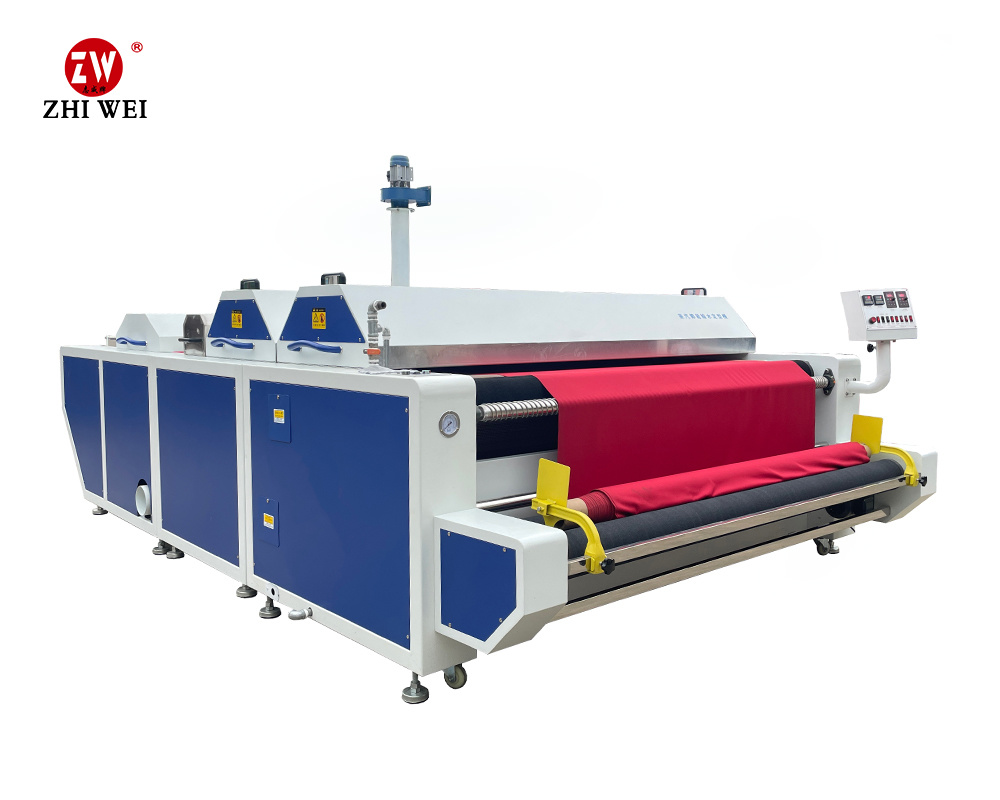

ZW-SN-518 Large Energy-Saving Pre-Shrinking and Setting Machine

- Description

-

Product Name

Product Model

Large Energy-saving Pre-shrinking and Setting Machine

ZW-SN-518

Technical Parameters:

Voltage

Total Power

Steam Consumption

Operating Speed

Operating Width

Machine Dimensions

AC 220V

7KW

100-150kg/n

0-40m/min

2100mm

4600×2700×1900mm

(Manual measurement may have deviations)

Product Features:

This model is divided into high-temperature steam pre-shrinking zone, drying and setting zone, and cooling and setting zone.

Uses advanced heaters, low power consumption, energy-saving; the whole machine's power usage is about 40-60% less than traditional energy-saving models, with fast preheating time and steam heating temperature up to 250°C.

Double mesh belt with automatic edge adjustment; separate mesh belts for hot and cold transmission.

Photoelectric eye fabric monitoring: maintains a certain sag between fabric and conveyor belt, allowing fabric to be transported without tension.

Automatic fabric stacking device: neatly folds fabric back and forth through a swinging fabric rack.

Manual and automatic induction electronic length meter: accurately measures fabric length, switchable between yards/meters.

Equipped with universal casters for easy mobility.

Product Applications:

Suitable for fabric shrinkage and setting in medium and large garment factories or weaving mills.

Unique heated steam box design enhances shrinkage effect, meeting different customer needs to achieve ideal fabric shrinkage results.

Prevents size changes or deformation in finished garments, or eliminates concerns about fabric stretch and shrinkage during clothing design and production.

Applicable Fabrics:

Can be used for shrinkage and setting of various fabrics such as knitted fabrics, woven fabrics, denim, etc.

Uses imported heaters for fast preheating time; steam heating temperature can reach 250°C.

Equipped with electronic counter for convenient yard/meter conversion.

Made of genuine #304 stainless steel material to extend service life.

Nylon universal casters

Related Products

Product Consulting

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will contact you as soon as possible