Product Details

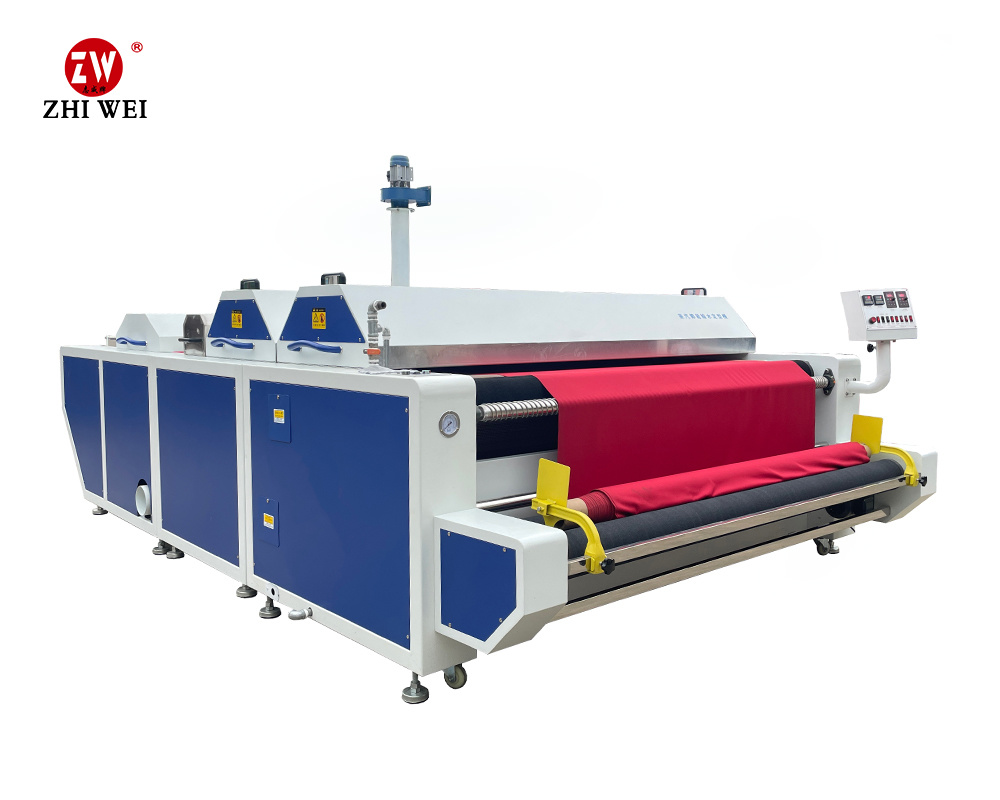

ZW-SN-8988 Large Intelligent Pre-shrinking and Setting Machine

- Description

-

Product Name

Product Model

High-end Large Intelligent Preshrinking and Setting Machine

ZW-SN-8988 with Rewinding Function

Technical Parameters:

Voltage

Total Power

Steam Consumption

Operating Speed

Operating Width

Machine Dimensions

AC 220V

8KW

90-130kg/n

0-60m/min

2100mm

4500+ (200) X 2700 X 1850mm

(Manual measurement may have deviations)

Product Features:

1. Uses a specially designed preshrinking method, copper tube heating, and intelligent temperature control to achieve energy-saving effects such as low steam and electricity consumption. The whole machine consumes about 5 kWh per hour (varies depending on usage and habits).

2. Equipped with an integrated touch screen control panel, making information clear and operation simple and convenient.

3. Uses foreign top brand Siemens controllers and touch display screens, domestic first-line brand electrical components, and low-voltage DC control circuits.

4. Uses imported heaters (steam heating up to 250°C) combined with high-temperature cloth to prevent large steam loss and temperature drop. The fabric contacts a wide range of steam, greatly improving fabric output efficiency and quality, solving most fabric preshrinking issues.

5. Automatic length counter that stops counting when no fabric is present and starts counting when fabric is present. It distinguishes between segment length and total length records. Segment length can be reset independently for easy calculation and recording of each fabric length, with unit switching between meters and yards.

6. The steam extraction box allows visible adjustment of suction power according to fabric thickness, and uses copper tube edging to prevent dripping and absorb steam moisture, making the discharged tail steam nearly transparent and invisible.

7. Uses high and low double conveyor belts running synchronously, distinguishing between high-temperature and low-temperature cooling belts.

8. Detachable independent control winding area, with optional winding function as needed.

9. Equipped with mobile universal wheels for easy movement and installation, and adjustable fixed feet to adapt to various complex floors.

10. Equipped with a printer for printing labels, facilitating recording of each fabric length, and can connect to a computer for easy data backup of each fabric roll.

Product Applications:

This machine is designed for medium and large garment manufacturing enterprises, weaving mills, and garment processing factories for fabric shrinkage and setting. It is the latest mechanical development of our company.

Fabric shrinkage processing softens untreated fabric, adjusts the silk yarn bias, stabilizes the original fabric size, and reduces shrinkage caused by sewing and ironing during garment production.

After shrinkage processing, fabric size is stable, hand feel is excellent, and it is less likely to shrink after re-ironing. This treatment ensures the best product quality and clearly increases added value.

Prevents size changes or deformation in finished garments, or frees you from worrying about fabric stretch and shrinkage issues during garment design and production.

Applicable Fabrics:

Suitable for shrinkage and setting of various fabrics such as knitted fabrics, woven fabrics, and denim.

Uses imported heaters with steam heating up to 250°C.

Equipped with electronic meter and printer for convenient recording of each fabric length.

Uses foreign top brands and domestic first-line brand electrical components.

Equipped with integrated touch screen control panel for easy operation.

Equipped with integrated touch screen control panel for easy operation.

Distinguishes between high-temperature conveyor belt and low-temperature cooling conveyor belt for synchronous transmission.

Automatic length counter that stops counting when no fabric is present and starts counting when fabric is present.

Made of genuine #304 stainless steel material to extend service life.

Specially designed preshrinking method, copper tube heating, and intelligent temperature control, with whole machine electricity consumption about 5 kWh per hour.

Related Products

Product Consulting

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will contact you as soon as possible