Product Details

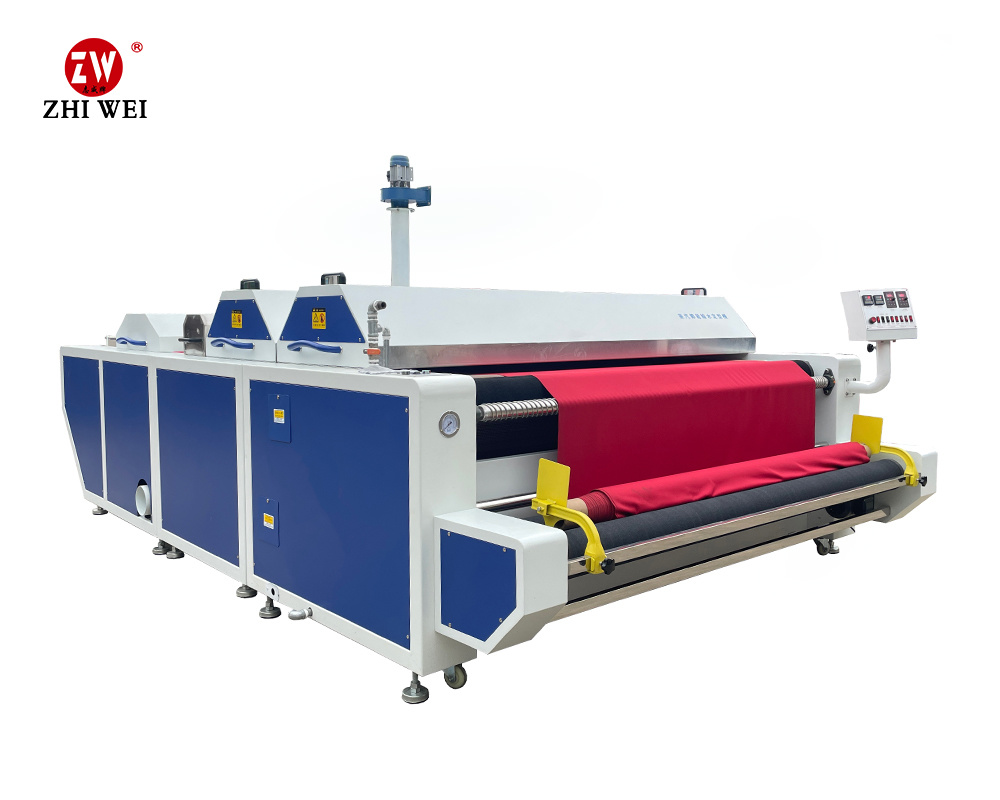

ZW-SN-8688S Large Intelligent Pre-shrinking and Setting Machine

- Description

-

Product Name

Product Model

Large Intelligent Pre-shrinking and Setting Machine

ZW-SN-8688S

Technical Parameters:

Total Power

Steam Consumption

Operating Speed

Working Width

Machine Dimensions

8KW

80-130kg/n

0-60m/min

2100mm

4550(+250)X2740X1920mm

Product Features:

The fabric feeding area is equipped with an equal fabric placement mechanism, combined with a foot pedal pause function, greatly reducing the possibility of fabric dropping or jamming due to excessive speed during feeding and material changing.

Guide Shaft: The power source for transmission. Driven by a three-phase gear reduction motor with variable frequency speed control, allowing convenient stepless speed adjustment.

Photoelectric Eye: Controls automatic fabric feeding amount, maintaining a certain fabric sag, so that the fabric entering the pre-shrinking area is tension-free and uniform.

Anti-deviation Belt Device: Micro switch sensing effectively prevents the occurrence of conveyor belt deviation.

Steam Area: The main working area of the machine, where fabric achieves pre-shrinking and setting through the action of double high-temperature steam. Heating temperature and steam volume can be selected according to different fabric fiber properties to meet various process requirements.

Uses imported heaters (steam heating up to 250°C). Unique and innovative electric heating device reduces production costs. All central pre-shrinking functional areas are made of high thermal efficiency materials, consuming less electricity and saving energy, with over 40% energy savings compared to ordinary models.

Drying Area: The fabric drying and heating treatment area, using steam copper pipes on both upper and lower sides combined with high-temperature aluminum plates for drying.

Dehumidifying, Cooling, and Setting Area: Uses downward vacuum suction to achieve fabric dehumidifying, cooling, and setting.

Fabric Collecting and Folding Area: Achieves back-and-forth folding of fabric through motor gearbox, with adjustable fabric swing width according to process requirements.

Newly equipped video monitoring for fabric feeding and output areas, greatly facilitating single-person independent operation and monitoring of fabric feeding and output status, reducing workers' frequent walking to observe feeding conditions.

Fabric Inspection Light Box: Allows observation of fabric impurities and defects.

Independently controlled fabric rolling area, with manual speed adjustment to control fabric rolling tightness and other operations.

Automatic Length Measuring Device: Automatically measures fabric length and stops measuring when fabric is finished (can convert between meters and yards).

Equipped with a printer for label printing, convenient for recording the length of each fabric roll, can connect to a computer for easy data backup of each fabric roll.

Product Applications:

This machine is designed for medium and large garment manufacturing enterprises or weaving mills and garment processing factories for fabric shrinkage and setting, developed as our company's latest machinery.

Fabric shrinkage processing softens untreated fabric, adjusts the silk yarn bias, stabilizes the original fabric size, and reduces shrinkage caused by sewing and ironing during garment production.

After shrinkage processing, fabric size is stable with excellent hand feel, and it is less prone to shrinkage after re-ironing, ensuring optimal product quality and clear added value.

Applicable Fabrics:

Can be used for various fabrics such as knitted fabric, woven fabric, denim, etc., for shrinkage and setting.

Advantages of imported heaters, steam heating up to 250°C.

Equipped with electronic counter and printer for convenient recording of each fabric roll length.

Video monitoring for fabric feeding and output areas.

Added backup controller.

Distinguishes synchronous transmission of high-temperature conveyor belt and low-temperature cooling conveyor belt.

Added hot pressing plate heating.

Fabric feeding area equipped with fluorescent light box for clear fabric inspection.

Fabric feeding area equipped with foot pedal pause feeding function.

Fabric feeding area equipped with foot pedal pause feeding function.

Related Products

Product Consulting

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will contact you as soon as possible