Product Details

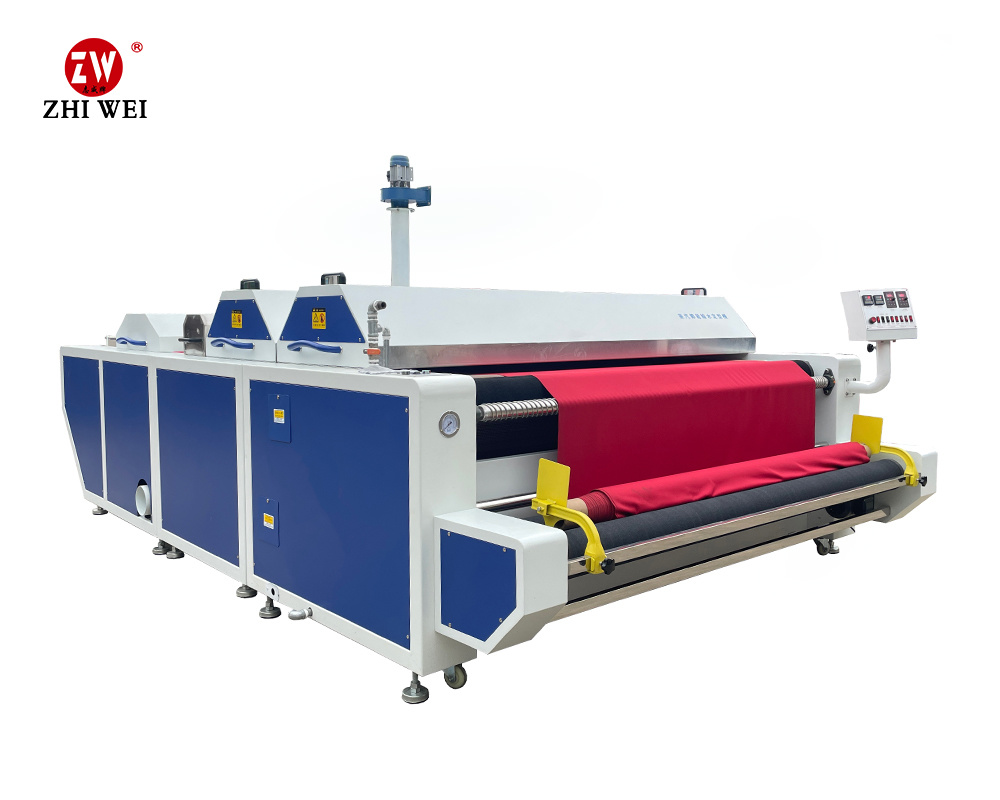

ZW-SK-382 Large Fabric Pre-shrinking and Setting Machine

- Description

-

Product Name

Product Model

Large Fabric Pre-shrinking and Setting Machine

ZW-SK-382

Technical Parameters:

Voltage

Total Power

Steam Consumption

Operating Speed

Working Width

Machine Dimensions

AC380V

20KW

80-100kg/h

0-40m/min

2100mm

4000×2700×2000mm

(Manual measurement may have deviations)

Product Features:

This model is divided into high-temperature steam zone, drying and setting zone, and cooling and setting zone.

Teflon conveyor belt, heat-resistant and high-temperature resistant corrosion protection used in pre-shrinking areas.

304 stainless steel material for corrosion and rust prevention.

Independent variable frequency speed control for conveyor belt and fabric feeding shaft.

Automatic edge adjustment of mesh belt; if the mesh belt deviates, the machine will automatically stop to prevent belt damage.

Imported heater used, temperature can reach 250℃, energy-saving and environmentally friendly.

Cooling device: uses a powerful exhaust cooling system.

Photoelectric eye monitoring for fabric feeding: maintains a certain sag between fabric and conveyor belt, allowing tension-free fabric transmission.

Dynamic fabric stacking device: fabric is neatly folded back and forth by a swinging fabric rack.

Steam extraction hood device: absorbs residual waste steam in the steam zone.

Counter: measures fabric length.

Equipped with universal casters and adjustable feet for easy movement and height/level adjustment.

Product Applications:

Suitable for medium and large garment manufacturing enterprises or weaving mills for fabric shrinkage and setting.

Fabric is moistened by steam and relaxed by vibrator, softening the fabric.

Fabric passes through preheating zone then enters drying zone, allowing moist fabric to dry at optimal temperature.

Powerful exhaust cooling system rapidly cools fabric, achieving setting effect through temperature difference.

Applicable Fabrics:

Can be used for shrinkage and setting of various fabrics such as knitted fabric, woven fabric, denim, etc.

Related Products

Product Consulting

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will contact you as soon as possible